Contributing to decarbonization with carbon capture and storage

Chemical and petrochemical sites require high-quality water for cooling purposes, production processes, and to feed steam boilers. Typically, in the past, the location of these plants was close to areas with an abundance of surface water and integrated with a port to allow the transportation of raw materials and finished products via sea.

More recently, ESG criteria and circular economy principles have allowed for the transformation of large petrochemical production sites. In operation since 1958, the Ravenna site is a production complex served by a large industrial port and integrated into one of the most dynamic districts in Europe. Production activities in the area range from natural gas to circular chemistry, and from power generation to environmental rehabilitation.

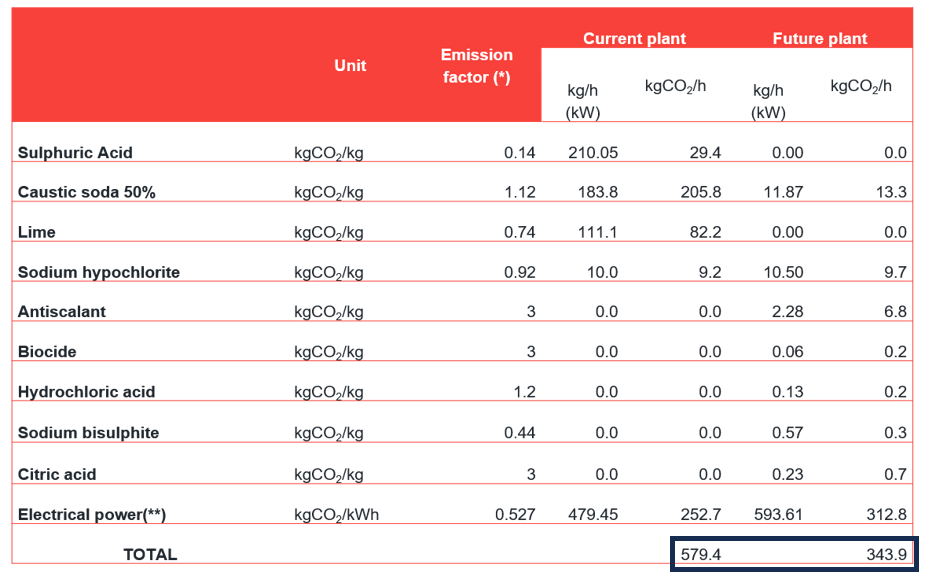

Operating in Ravenna, ENI recently initiated the development of the Carbon Capture and Storage (CCS) project, which involves building a CO2 storage infrastructure. Carbon dioxide is captured at the source and then transported and stored in the depleted gas fields of the Adriatic Sea. The goal is to contribute to reducing the emissions of industrial districts to make them more sustainable and competitive in the market, thereby creating the conditions for new opportunities for economic growth through decarbonization.

As part of the integration between chemical/petrochemical production and the surrounding environment, optimizing overall water management while leveraging the nexus between water and energy becomes essential. In that context, the water treatment plant designed by WSP plays an instrumental part.

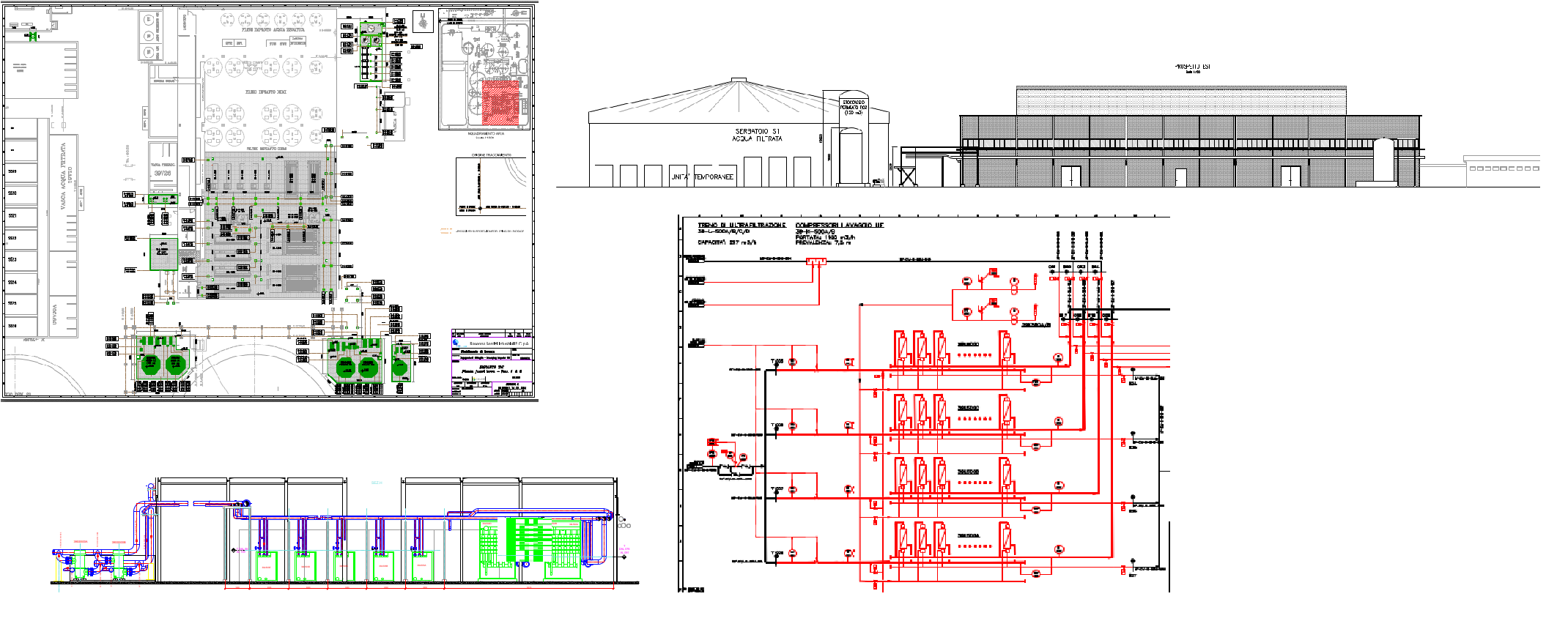

Designing a water treatment plant fit for purpose

Utilities for the petrochemical site and all the surrounding industrial areas have been managed by Ravenna Servizi Industriali (RSI) since 2004. In the second half of 2010, specific existing water treatment plants, designed to produce soft and demineralized water from river water (based on clariflocculation, sand filtration, and ion exchange units), needed revamping to cope with new production units and infrastructure aging.